TS-199 series pocket setter is a high-speed automatic sewing machine for garment pocket sewing. These pocket setter machines have high sewing precision and stable quality. Compared with the traditional manual production, the work efficiency is increased by 4-5 times. One pocket setter machine can simultaneously complete the positioning, folding and sewing of pockets. One operator can operate two pocket setter machines, and the work efficiency can be as high as 2500-3000 pieces/8 hours.

TS-199 series advantages:

1, It is not only suitable for woven fabrics, but also for knitted fabrics and denim fabrics.

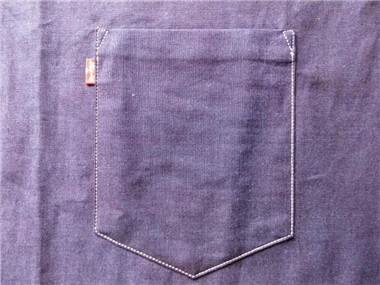

woven fabric

knitted fabric

2, The sewing precision is high, and the seam to pocket margin (0.5mm-0.8mm) is even.

3, Customized mold, can meet all types of pocket styles, according to the changing trend of the market to quickly respond to ensure customer market share.

4, Personalized process. Visual touch screen, easy to operate in multiple languages. The friendly user operating system enables the operator to quickly enter the working state, complete the setting of various parameters and observe the operation of the pocket setter machine.

5, Easy to maintain, mold replacement is very convenient. The whole set of mold replacement can be completed within 8 minutes, greatly improving the production efficiency

6, Hardware configuration is in line with the industry's first-class standards. Equipped with heavy machine head, all electronic components are made by world famous manufacturers.

The biggest advantages of the pocket setter machine are: folding pocket, sewing, collecting materials in one go, high-speed sewing, suitable for all kinds of fabrics, customized mold, personalized technology, easy operation, fast mold changing, and exquisite sewing. Besides, the biggest characteristic of pocket setter is sewing double line shirts and jeans pockets.

Post time: Dec-30-2020