melt blown fabric for face mask

With the continuous spread of the global epidemic situation, the demand for epidemic prevention materials in countries around the world is increasing. Our company cooperates with large domestic companies to meet the needs of domestic epidemic prevention, and at the same time, we are making every effort to provide urgently needed materials for the global fight against the covid-19.The covid-19 situation in China has been basically controlled, and the prices of non-woven fabrics and meltblown fabrics are falling sharply, which can save a lot of costs for foreign customers. At the same time, we can ensure the improvement of product quality, so that customers can buy better products at the best price, and realize customers' continuous return orders.We offer good quality and price, welcome to the global buyers to consult.

Melt-blown nonwoven uses polypropylene as the main raw material. The fiber diameter canreach 1to5um. There are many voids, fluffy structure and good fold resistance. The Melt-blown nonwoven has unique capillary structure which increases the number and surface area of fibers per unit area, so that the melt-blown nonwoven has good filtering, shielding, heat insulation and oil absorption.

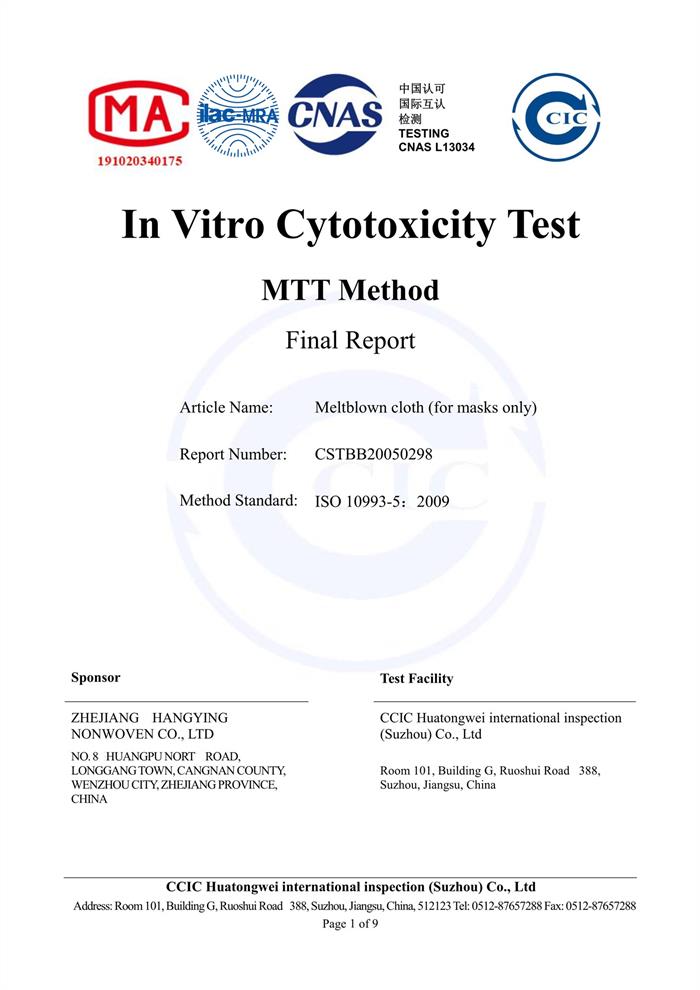

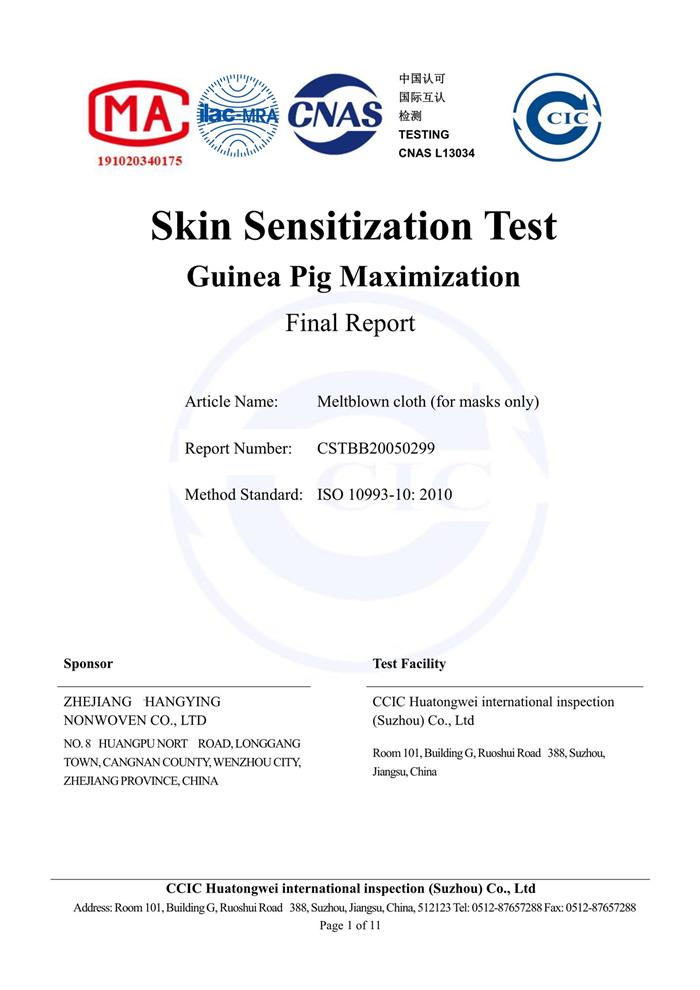

Melt-blown nonwoven is the core material of the mask. Melt blown fabric have powerful filtration performance, outstanding advantages in filtration, becteria resistance, adsorption, etc.

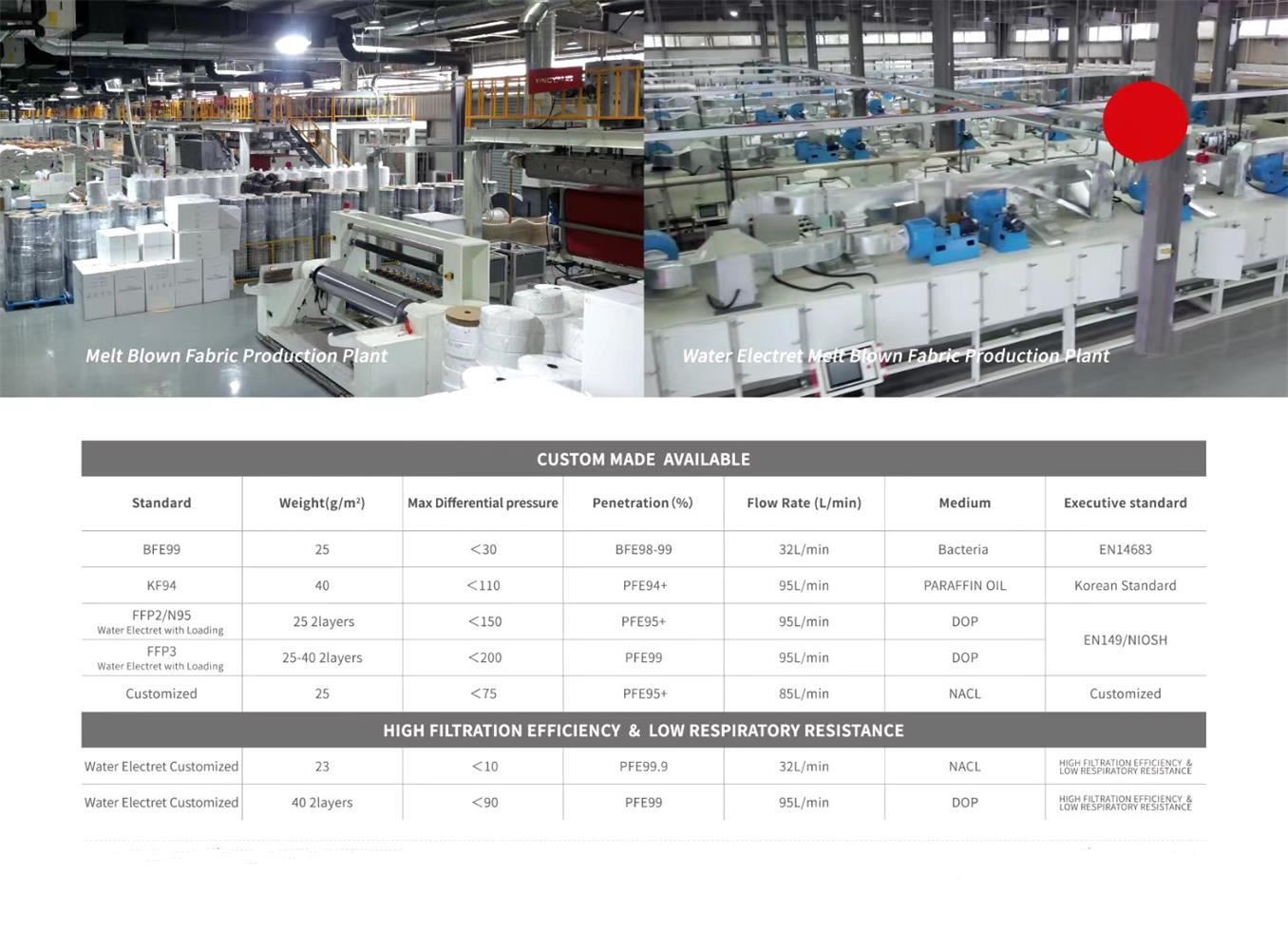

PRODUCTION METHOD

A high-speed hot air flow draws a thin stream of polymer melt extruded from the die orifice of the die which form ultra-fine fibers. Then, we collect them on the condensed screen or roller and at the same time bonding themselves to become Melt-blown nonwoven fabric.

Meltblown process

Polypropylene PP particles→melt extrusion→metering pump→melt-blown die head assembly→melt fine flow stretching→cooling→receiving device→electrostatic electret→trimming winding machine

Meltblown equipment

Main equipment: feeding machine, screw extruder, metering pump, melt-blown die head assembly, air compressor, air heater, receiving device, electrostatic electret, winding device.

The production line is equipped with the most excellent abrasive tools, Sanxin electrostatic electret, high-quality melt blown materials of Jinfa technology, and professional laboratory and imported inspection equipment to ensure the production of high-quality melt blown fabric. Overcome the decline of static electret and ensure the long-term electret of meltblown cloth.

Multiple characteristics of meltblown cloth: in accordance with the standards of GB / T32610-2016, GB / 19083-2010, YY / T0969-2013 (disposable medical mask), YY / T0469-2011 (medical surgical mask), etc., it can also be produced according to the needs of customers.

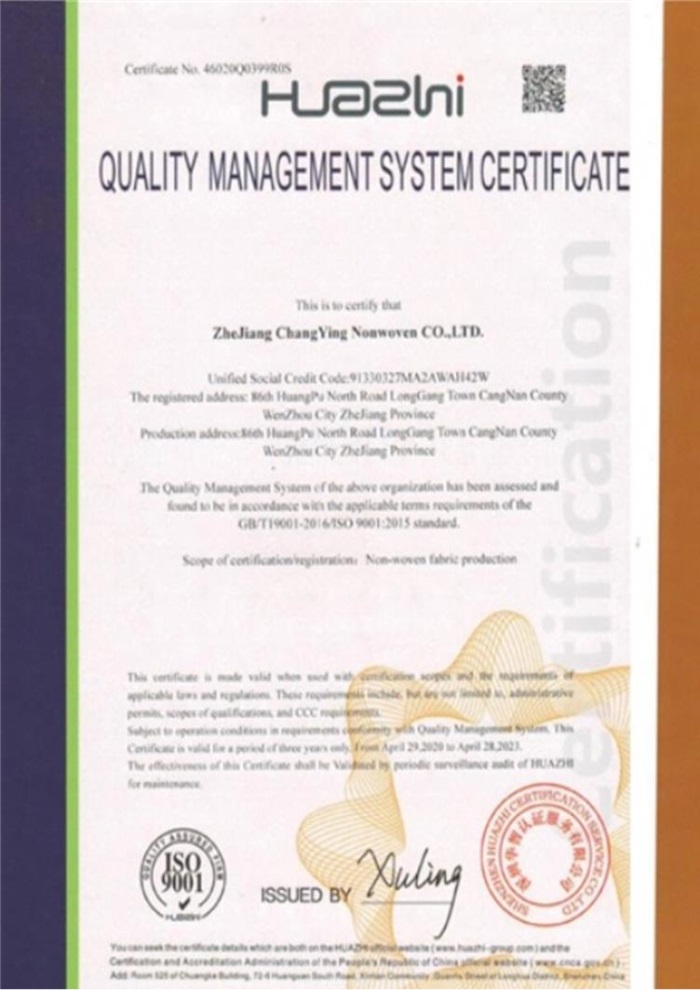

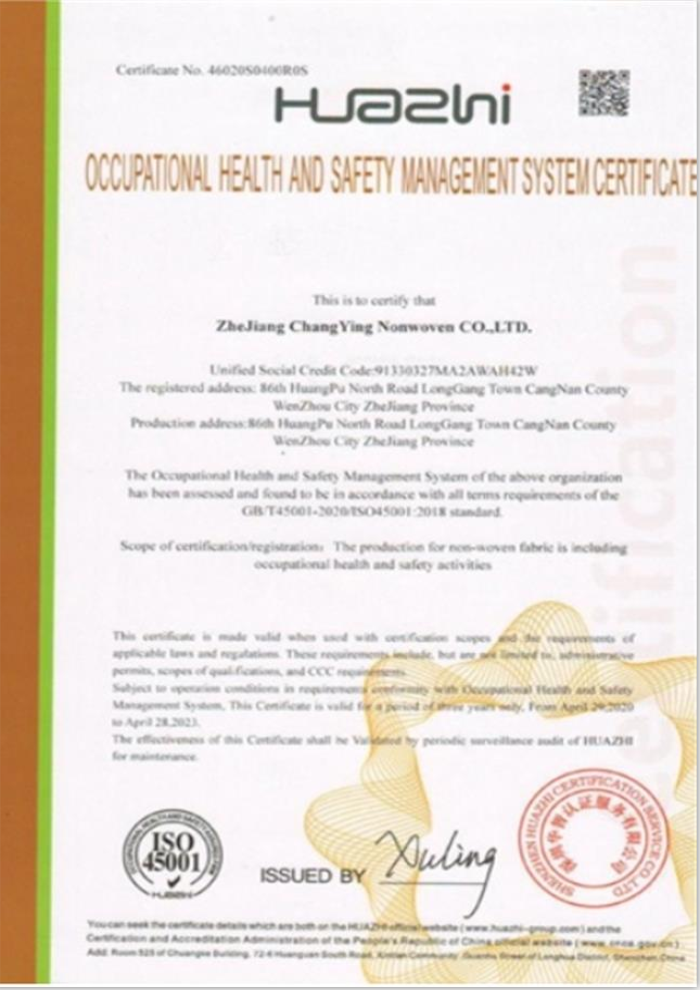

AlI products are in a standardized production process, Quality reliably.

Filtration efficiency is one of the important performances of masks. Different masks have the function of filtering dust, toxic gases and germs. Therefore, the level of filtration efficiency directly reflects the quality of the mask.

The melt-blown cloth used as a mask needs to be tested in strict accordance with the standards. The filtering effect is one of the most important testing items. Aerosol particles of a certain concentration and particle size distribution are generated by the aerosol generator, pass the mask cover at a prescribed gas flow rate, and the particle concentration before and after passing through the mask cover is detected using an appropriate particle detection device. The filtration efficiency of the mask body to the particulate matter was evaluated as the percentage of the reduction in the concentration of particulate matter after the aerosol passed through the mask body. The efficiency of the melt-blown cloth produced by our company is 99.1%.