Welcome to our websites!

- Email: doris@chinatopsew.com

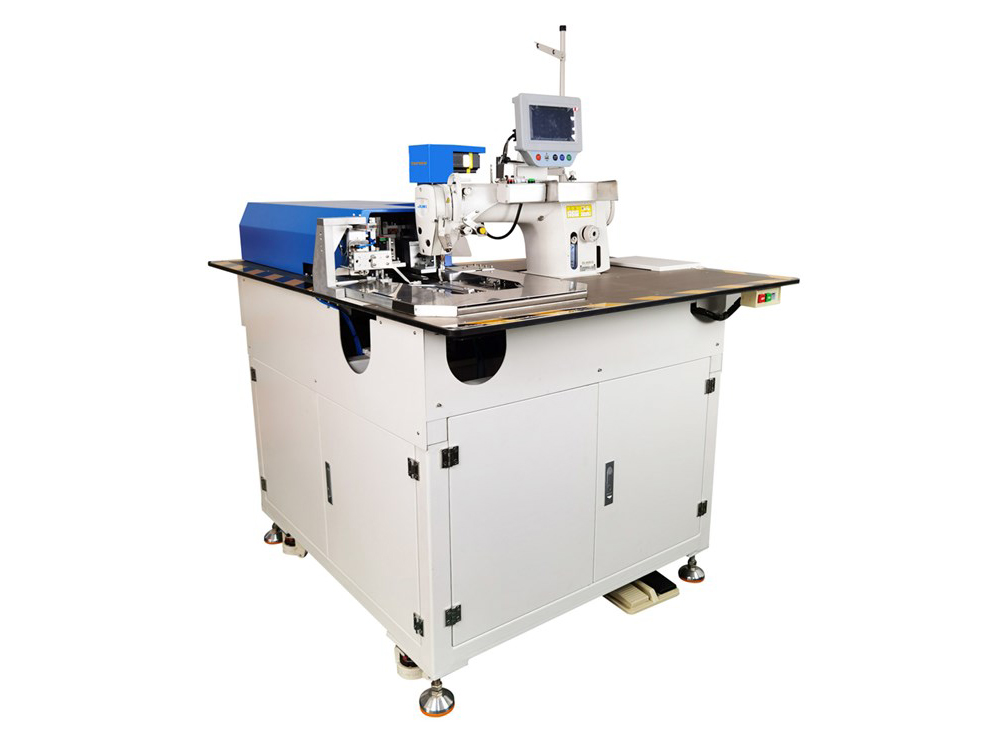

Automatic Shirt Sleeve Slitting Machine TS-850

1.One person can operate two shirt sleeve slitting machines at one time. The speed is 4-5pcs/min.

2.One shirt sleeve slitting machine can realize switching and sewing of left and right sleeves, no need to change another mold.

3.Sleeve gap mold structure can realize quick change.

4.The lower support magnetic device can improve the stability of sleeve folding.

5.The electronic follow-up auxiliary presser foot device ensures the stability of sewing.

6.Wide range of applicable fabrics (normal shirt fabric, non-iron shirt fabric, knitted fabric, etc.).

7.Machine head moves in the X-axis direction and the sleeve mold moves in the Y -axis direction, which can meet the sewing accuracy.

| Size of sleeve length: | 50-200mm, width 18-50mm. |

| Work Speed: | 3000rpm(MAX) |

| control System: | singlechip |

| stitch length: | 0.5-2.0mm |

| Power: | 2Kw |

| Power Supply: | 22ov single phase 50/60Hz |

| Air Pressure: | 0.5Mpa(5Kgf/cm2) |

| Machine weight: | 395kg |

| Machine measurement: | 1400mmX1070mmX1270mm |

Write your message here and send it to us