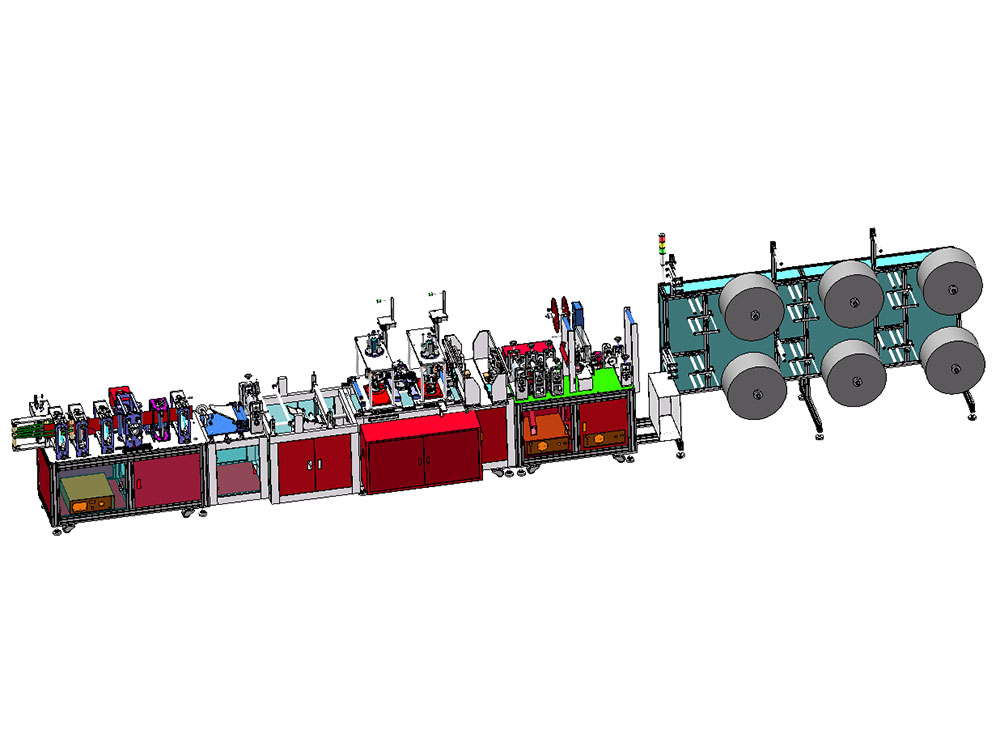

Automatic KN95 / N95 earloop mask making Machine

Technical Parameters & Configuration Requirements

(1) Production Standards: Based on the side of the product drawing provided by the first-party;

(2) Equipment overweight: 3000KG;

(3) UPH: over 2400;

(4) Qualified rate: 98%;

(5) Equipment failure rate: 2%;

(6) Number of operating personnel:1;

(7) Electronic control mode: PLC;

(8) Driving mode: servo motor;

(9) Control board: touching screen+buttons;

(10) Equipment size: 9800mm(L)×1500mm(W)×2100mm(H);

(11) Equipment color: White:HCV-N95-A;

(12) Power supply: single phase:220V,50HZ,rated power: about 14KW;

(13) Compressed air: 0.5~0.7 MPa, flow:about300L/min;

(14) Environment: temprature:10~35℃, humidity:5-35%HR, no flammable, corrosive gas, workshop with the standard of no less than 100000 level dust-free;

Major Components of the Equipment

| No. | component name | quantity | remark |

| 1 | Water-filting cloth /melt-blow cloth/ roll of water-accepting layer loading | 6 | |

| 2 | roll of nose-line loading | 1 | |

| 3 | Drive & cutting of the nose bridge strips | 1 | |

| 4 | Edge sealing structure | 1 | |

| 5 | Cloth-driving structure | 1 | |

| 6 | ear-band welding structure | 2 | |

| 7 | blanking structure | 1 | |

| 8 | Operation system | 1 | |

| 9 | Operation board | 1 | |

| 10 | Hand-holding welder | 1 | Selective, for cloth rolling |

| 11 | Structure for Punching & cutting of the holes of Breathing valve | 1 | Selective, installed on the automatic line |

| 12 | Welder for Manual breathing valve | 1 | Selective, manual operation offline |

Supplied materials& specification standard

| project | width(mm) | external diameter of roll material (mm) | internal diameter of charging barrel (mm) | weight | remark |

| non-woven cloth(attach to face) | 230-300±2 | Φ600 | Φ76.2 | Max 20kg | 1layer |

| non-woven cloth(outermost layer) | 230-300±2 | Φ600 | Φ76.2 | Max 20kg | 1layer |

| filter layer in the middle | 230-300±2 | Φ600 | Φ76.2 | Max 20kg | 1-4layer |

| Stripes of nose bridge | 3-5±0.2 | Φ400 | Φ76.2 | Max 30kg | 1roll |

| ear-band | 5-8 | - | Φ15 | Max 10kg | 2rolls/box |

Equipment safety

Equipment safety requirements

(1) The design of the equipment conforms to the principle of man-machine, convenient and safe operation, and the whole equipment is firm and reliable.

(2) The equipment shall be provided with good and comprehensive safety protection measures. The rotating and dangerous parts on the equipment shall be provided with protective devices and safety signs, and the safety and environmental protections shall meet national standards.

Electrical safety requirements

(1) The whole machine is equipped with cut-off valves of power supply and air source to ensure no danger during the maintenance.

(2) The control system shall be set at the place convenient for the operator to operate and observe.

(3) The electrical control system of the equipment has the functions of overload protection and short circuit protection.

(4) The outlet of the distribution cabinet is equipped with measures to prevent the abrasion of wires.